source: tribune.com

In the realm of aquaculture, where sustainability is paramount, innovative solutions are continually sought to meet the growing demand for seafood while minimizing environmental impact. One such groundbreaking technology that has been making waves in recent years is Biofloc Construction. In this blog, we’ll delve into the construction and functionality of biofloc systems, shedding light on their role in revolutionizing modern aquaculture practices.

Understanding Biofloc Construction:

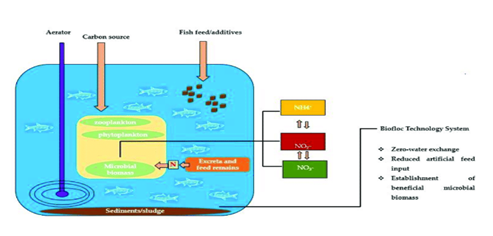

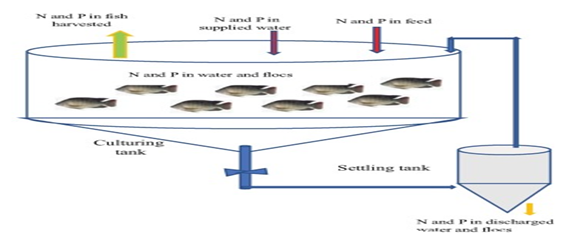

At the heart of Biofloc Technology lies the construction of biofloc systems, which are designed to create and maintain a dynamic ecosystem of suspended organic matter and microorganisms within aquaculture environments. The construction of a biofloc system typically involves several key components:

- Pond or Tank Setup: Biofloc systems can be implemented in ponds, tanks, or other enclosed aquatic environments. These structures provide the physical space for cultivating bioflocs and rearing aquatic species.

- Aeration Systems: Aeration is essential for maintaining oxygen levels in the water and promoting the growth of aerobic microorganisms within the biofloc system. Various aeration devices, such as air diffusers or paddlewheel aerators, may be employed to ensure adequate oxygenation.

- Carbon Source Addition: To stimulate microbial growth and create bioflocs, a carbon source is introduced into the system. Common carbon sources include molasses, carbohydrates, or commercial carbon supplements. These serve as food for the microbial community and facilitate the formation of bioflocs.

- Water Quality Monitoring: Regular monitoring of water quality parameters, such as pH, temperature, ammonia, and nitrite levels, is crucial for ensuring optimal conditions within the biofloc system. This helps maintain a healthy microbial community and promotes the growth of cultured species.

Biofloc systems function by harnessing microbial processes to create a suspended growth of organic matter, phytoplankton, bacteria, and grazers within the aquaculture environment. This dynamic ecosystem serves as both a natural source of nutrition for cultured organisms and a means of water treatment. The microbial community present in bioflocs plays a vital role in recycling nutrients, mitigating waste, and improving water quality.

Conclusion:

As the aquaculture industry continues to evolve, Biofloc Construction stands out as a pioneering technology with the potential to revolutionize modern fish farming practices. By harnessing the power of microbial communities and promoting sustainability, biofloc systems offer a promising solution to meet the growing demand for seafood while minimizing environmental impact. As we continue to explore and refine biofloc construction techniques, we pave the way towards a more sustainable and prosperous future for aquaculture

Frequently Asked Questions (FAQs)

What is Biofloc Construction?

Biofloc Construction involves creating a dynamic ecosystem of suspended organic matter and microorganisms within aquaculture environments.

How does Biofloc Construction differ from traditional aquaculture systems?

Unlike traditional systems, Biofloc Construction utilizes microbial processes to recycle nutrients, improve water quality, and promote sustainability in fish farming.

What are the key components of a biofloc system?

A biofloc system typically includes a pond or tank setup, aeration systems, carbon sources, and regular water quality monitoring.

What are the benefits of Biofloc Construction in aquaculture?

Benefits include enhanced water quality management, increased productivity, reduced environmental impact, and improved disease control.

How can aquaculturists effectively implement Biofloc Construction?

By carefully designing and maintaining biofloc systems, monitoring water quality, providing adequate aeration and carbon sources, and integrating biofloc technology into overall farm management practices.